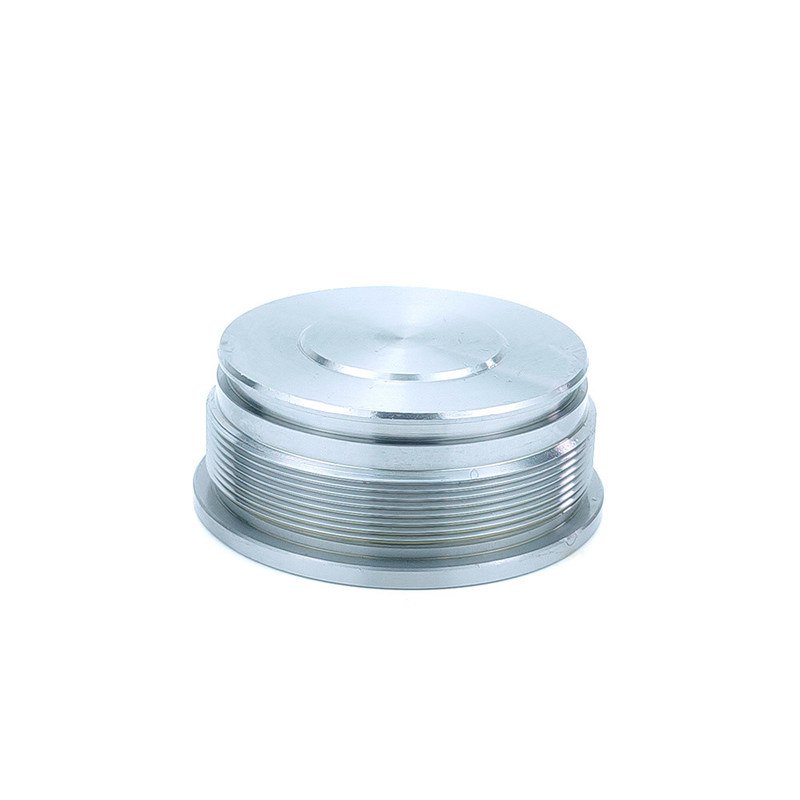

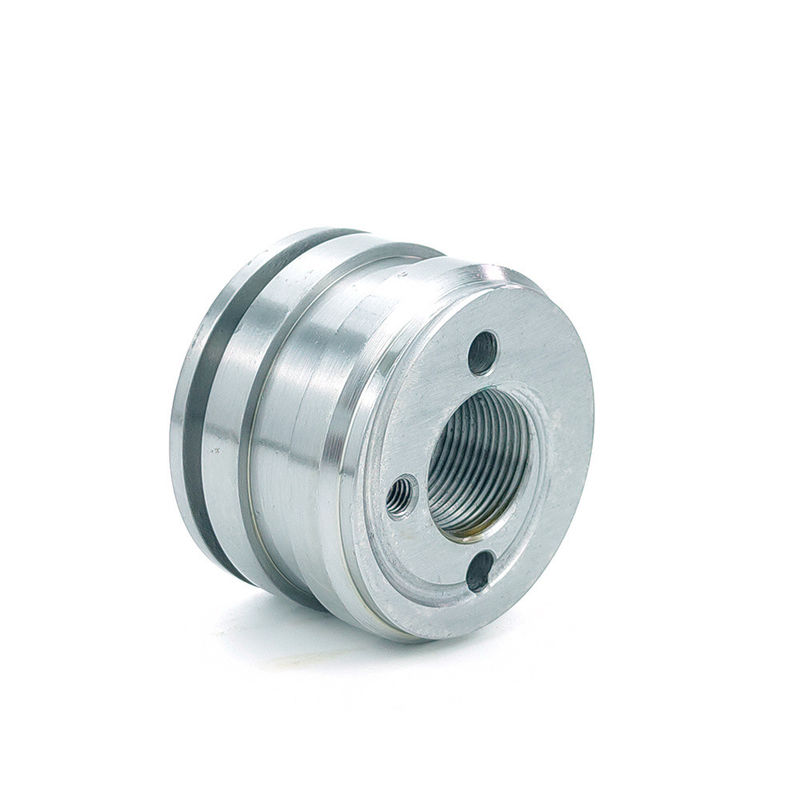

Name: OEM High Precision Steel Sleeve Machinery Parts for Auto Parts

You will get *. Inquiry will be replied in 24 Hours

*. No-Standard/Standard/ OEM/ODM Customized service provided

*. Cheap Price

*. Small order available

*. Free samples sometimes

*. Fast lead time

*. Timely after-sales services

Description | Material available | *.Stainless Steel: SS201, SS303, SS304, SS316 etc.

*.Aluminum: 6061, 6063,7075,5052 etc.

*.Carbon Steel: AISI 1045, 9SMnPb28 etc

*.Brass:C36000 (C26800), C37700 (HPb59), C38500(HPb58), C27200(CuZn37), C28000(CuZn40) etc.

*.Bronze: C51000, C52100, C54400, etc.

*.Iron: grey iron and ductile iron |

| Application Industry | Mechanical components for engineering and construction, , Aerospace, Medical device, Auto, Telecommunications, Defense parts & electronic processing Equipment parts, Motorcycles, Railway ,Marine Industry etc. |

| Processing method | CNC Cutting, CNC Milling, CNC Lathing, Drilling, punching, grinding, broaching, welding ect |

| Surface Treatment | Sand blasting, polishing, Anodize, zinc/nickel/chrome/ plating, Power coating, passivation,Blacken, Hardening, Painting |

| Quanlity control | *.Incoming inspection

*.Production line inspection *.100% inspection before shipment |

| Tolerance | ± 0.05mm |

How Ace Sure The Quality?

1) Ace proceed 4 times during production proceeding.

They are: raw material inspection, process machining inspection, mass production inspection, final inspection.

2) After each inspection, a paper report will be checked out and recorded for future checking.

3)100% Inspected before Shipment. Inspection date report provided. And PPAP can be provided too.

How Many Equipments Does Ace Have?

10 CNC lathing machine with actual working tolerance ±0.02MM.

5 CNC lathing and milling center with actual working tolerance is ±0.02MM.

Drawing Format Can Done By Ace?

dwg, dxf, prt, iGS, step, stp, iges, slprt, asm, x_t files are all accepted.

What kinds of CNC machining product is suitable to send to Ace for quoation?

CNC machining product, CNC milling product, CNC lathing product, CNC turning product, CNC precision machining product, maching product, precision product and all machining parts used in different industrials such as: spray nozzle, car accessories, railway accessories, bathroom accessoires, equipemnt spare parts, pipe and fittings and so on.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!